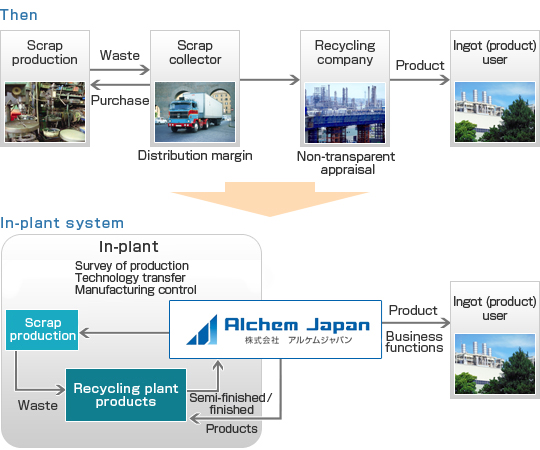

We propose in-plant recycling systems for rare metals (e.g. recovery of indium from blasting waste containing ITO scrap or cleaning waste fluid containing 1% or more indium). Materials that were previously discarded and assets that were processed non-transparently can be recovered at your site for fair and proper evaluation. This can also reduce distribution costs. There are many more ways our group’s technology may be able to help you. Drop us a line and we will see what we can do.

We propose in-plant recycling systems for rare metals (e.g. recovery of indium from blasting waste containing ITO scrap or cleaning waste fluid containing 1% or more indium). Materials that were previously discarded and assets that were processed non-transparently can be recovered at your site for fair and proper evaluation. This can also reduce distribution costs. There are many more ways our group’s technology may be able to help you. Drop us a line and we will see what we can do.

Material survey

We investigate the raw materials (waste and recyclable resources) you have. We conduct analysis, feasibility studies, and route checks, under a non-disclosure agreement.

We investigate the raw materials (waste and recyclable resources) you have. We conduct analysis, feasibility studies, and route checks, under a non-disclosure agreement.

Formal contract

After you review the results of our analysis, we make a formal contract. We secure laborers, build a system (documents and shipping), inspect the feasibility study, and order equipment.

After you review the results of our analysis, we make a formal contract. We secure laborers, build a system (documents and shipping), inspect the feasibility study, and order equipment.

Plant installation, recycling

We make labor contracts, train laborers, provide technology, and start operation. We provide thorough follow-up service and support the progress of insourcing.

We make labor contracts, train laborers, provide technology, and start operation. We provide thorough follow-up service and support the progress of insourcing.

Purchase, evaluation

We appraise and purchase the products of recycling. We take full responsibility for holding up our end, going as far as cash payment.

We appraise and purchase the products of recycling. We take full responsibility for holding up our end, going as far as cash payment.